Playing with pan widths is an effective way to create an original and eye catching metal facade.

When specifying metal cladding, it’s important to remember in addition to material and system selection, you must also consider panel size, lay direction, join styles, corner details, and the list goes on. Today, we’re going to focus on cladding system size and in particular, panel width.

When we talk about “a system” there is an assumption that fixed sizes apply. However our metal cladding is not an off-the-shelf product. All roof and wall cladding is custom made on a project specific manufacturing model. This production method means panel sizes are not fixed, but open to customisation. Specifiers can dictate almost any dimensions, within minimum and maximum ranges. In addition to different pan widths, applications can also mix random panel sizes, combine similar width sheets to form a pattern, or keep things uniform and identical.

While panel size selection is ultimately up to you, at Metal Cladding Systems we do have “preferred” panel widths for each system. These are determine by material coil dimensions and are calculated more precisely by taking into consideration each profile’s design, and the amount of metal folding and rolling required. Remember, panels can be made to any width within a system’s capabilities, our preferred sizes are only a guide and focus specifically on minimising material waste.

The best way to understand panel widths is to look at each cladding system individually and discuss design opportunities and limitations.

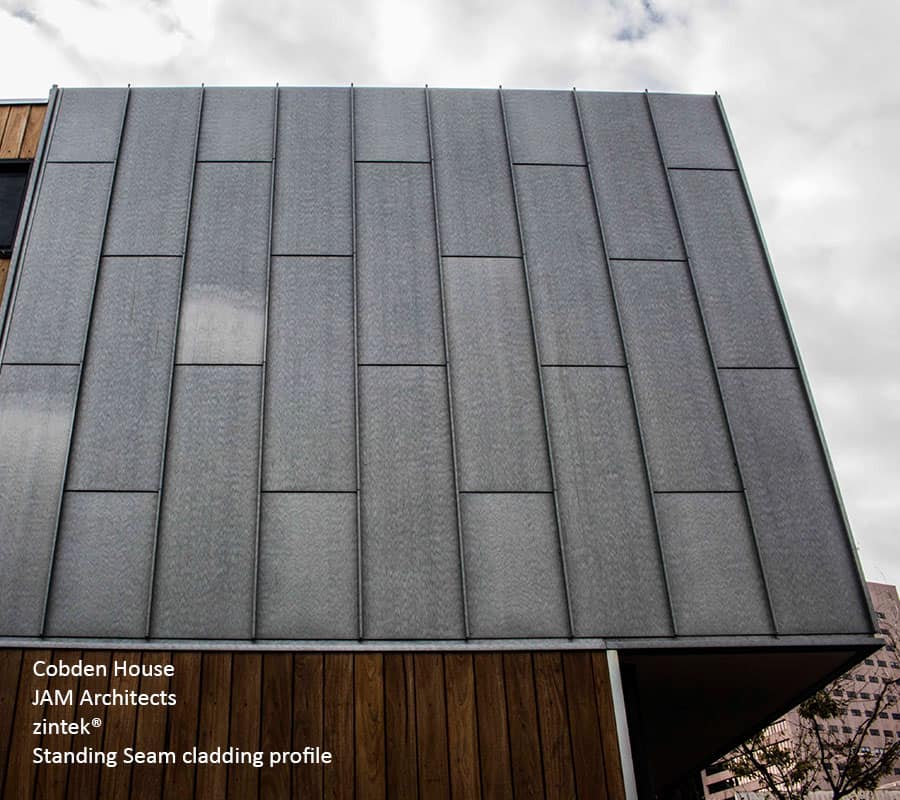

Standing Seam

Standing Seam is one of the most popular cladding systems in our market. It offers timeless charm that suits both modern and traditional architectural styles. Standing Seam is available in a wide variety of materials and can be manufactured in an enticing array of panel sizes.

Minimum and maximum widths: 180 mm to 530 mm (material dependant)

Standard Standing Seam panel widths:

- 25 mm rib – 230 mm, 330 mm, 530 mm

- 38 mm rib – 200 mm, 300 mm, 500 mm

(COLORBOND Steel®, Aluminium)

Standard Standing Seam panel widths:

- 25 mm rib – 263 mm, 430 mm

- 38 mm rib – 233 mm, 400 mm

(Zinc)

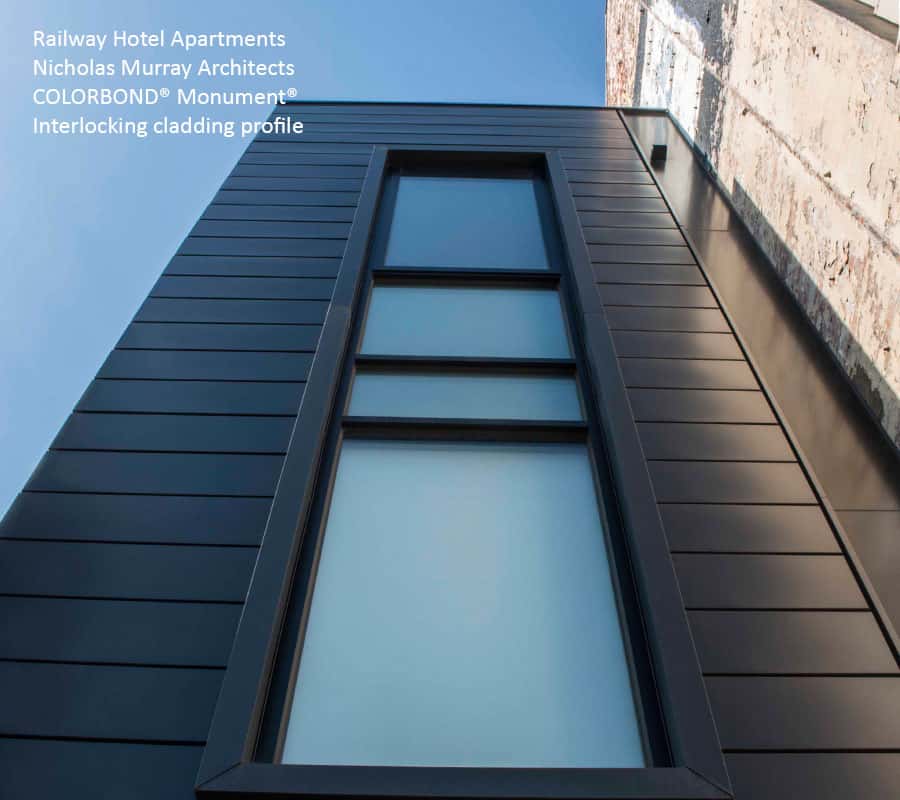

Interlocking

By using different panel and express join widths, Interlocking can completely transform from one application to another. With great material suitability and design flexibility, Interlocking has a never ending list of advantages to offer every application.

Minimum and maximum widths: 205 mm to 505 mm (material dependant)

Standard Interlocking panel widths: 205 mm, 305 mm, 505 mm

(COLORBOND Steel®, Aluminium)

Standard Interlocking panel widths: 238 mm, 405 mm

(Zinc)

Flatlock

As its name suggests, Flatlock’s panels lock together; creating a flush, flexible, and thin system. Because of the overlapping effect installed panels have, this profile is commonly specified as an alternative to traditional timber weatherboards.

Minimum and maximum widths: 140 mm to 540 mm (material dependant)

Standard Flatlock panel widths: 240 mm, 340 mm, 540 mm

(COLORBOND Steel®, Aluminium)

Standard Flatlock panel widths: 273 mm, 440 mm

(Zinc)

Shingle

Shingle cladding is always a showstopper. The tile, or scale looking system offers a dynamic metal facade solution, with very few limitations. When manufacturing Shingle panels we can make them to any dimensions within the minimum and maximum thresholds noted below.

Minimum and maximum widths: 140 mm to 340 mm (material dependant)

Standard Shingle widths: 240 mm, 340 mm, 540 mm

(COLORBOND Steel®, Aluminium)

Standard Shingle panel widths: 273 mm, 440 mm

(Zinc)

Snaplock

Offering a similar aesthetic to Standing Seam, Snaplock doesn’t require specialist tooling to install. Each panel is designed to “snap” together, allowing for quick onsite installation with an attractive finish.

Minimum and maximum widths: 165 mm to 500 mm (material dependant)

Standard Snaplock panel widths:

- 25 mm rib – 225 mm, 325 mm, 525 mm

- 38 mm rib – 195 mm, 295 mm, 495 mm

(COLORBOND Steel®, Aluminium)

Standard Snaplock panel widths: 233 mm, 400 mm (not recommended)

(Zinc)

Nailstrip

Nailstrip may not offer the same flexibility of other profiles (limited material suitability), but it does provide simple installation and an architectural facade solution. We mostly manufacture Nailstrip from COLORBOND® and find it’s a go-to specification for multi-residential projects or large scale commercial work.

Standard Nailstrip panel widths:

- 25 mm rib – 192 mm, 292 mm, 492 mm

- 38 mm rib – 165 mm, 265 mm, 465 mm

(COLORBOND Steel®)

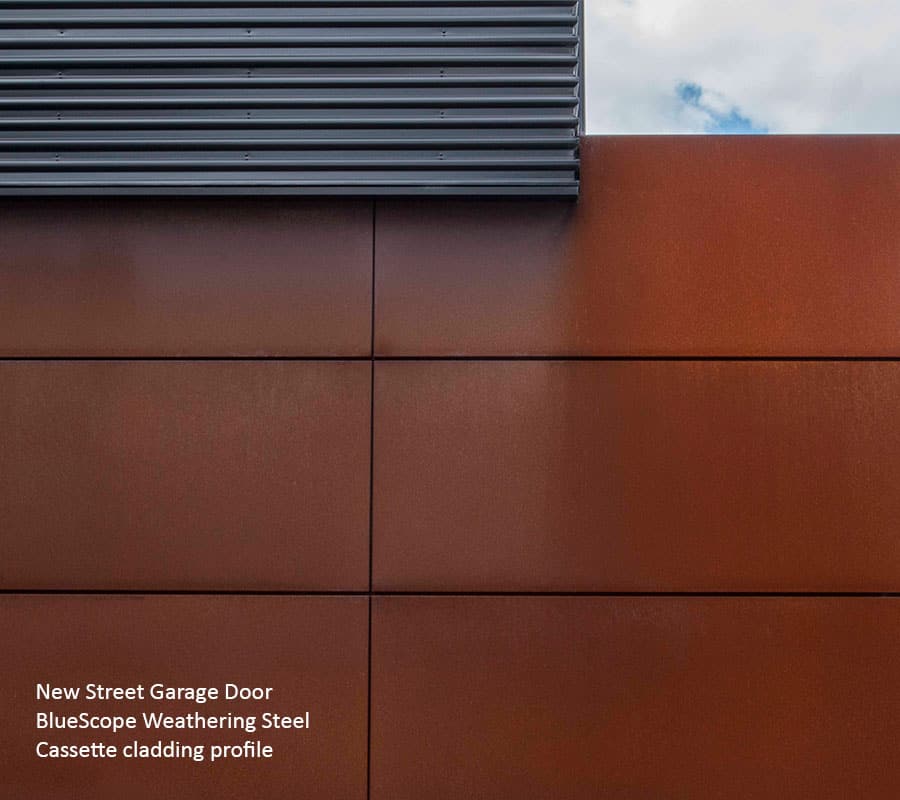

Cassette Panel

An ideal solution for projects that call for large commercial style panels. Cassette Panel is also worth looking at if you’re struggling to design within the limitations of our Interlocking system as Cassette Panels create very similar facade aesthetic.

Minimum and maximum widths: Panel sizes are flexible, any combination within the constrains of 1000 mm x 3000 mm, or 3000 mm x 1000 mm, are possible. (material dependant)

Batten Seam

Traditional and charming, we don’t see enough of this beautiful system in our market. Batten Seam offers impressive raised seams that showcase material specification and roof and wall shapes. Much like our Cassette Panel, Batten Seam is a flexible system, open to multiple panel widths within the profile’s maximum size constraints.

Minimum and maximum widths: 480 mm panel maximum width (material dependant)

For more detailed system information, visit our systems page by clicking the button below.

More cladding system information